GRC

is a lightweight cementitious material composed of

cement, fine aggregates, alkaline-resistant (AR) glassfibre,

water and admixtures. It is particularly useful where

durability, fire resistance and strength are required

but where weight is an issue.

GRC is used in engineering applications for cable

troughs, permanent formwork and equipment enclosures.

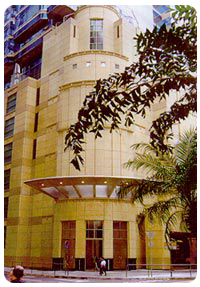

GRC is also ideal for architectural and decorative

applications and can be incorporated into curtain

wall systems.

Redland Precast has been awarded the Glassfibre

Reinforced Concrete Association International Award

on two occasions: for the Hong Kong City Plaza project

and for the Chinechem residential development at

129 Repulse Bay, Hong Kong.

|

Repulse Bay Road

|

|

|